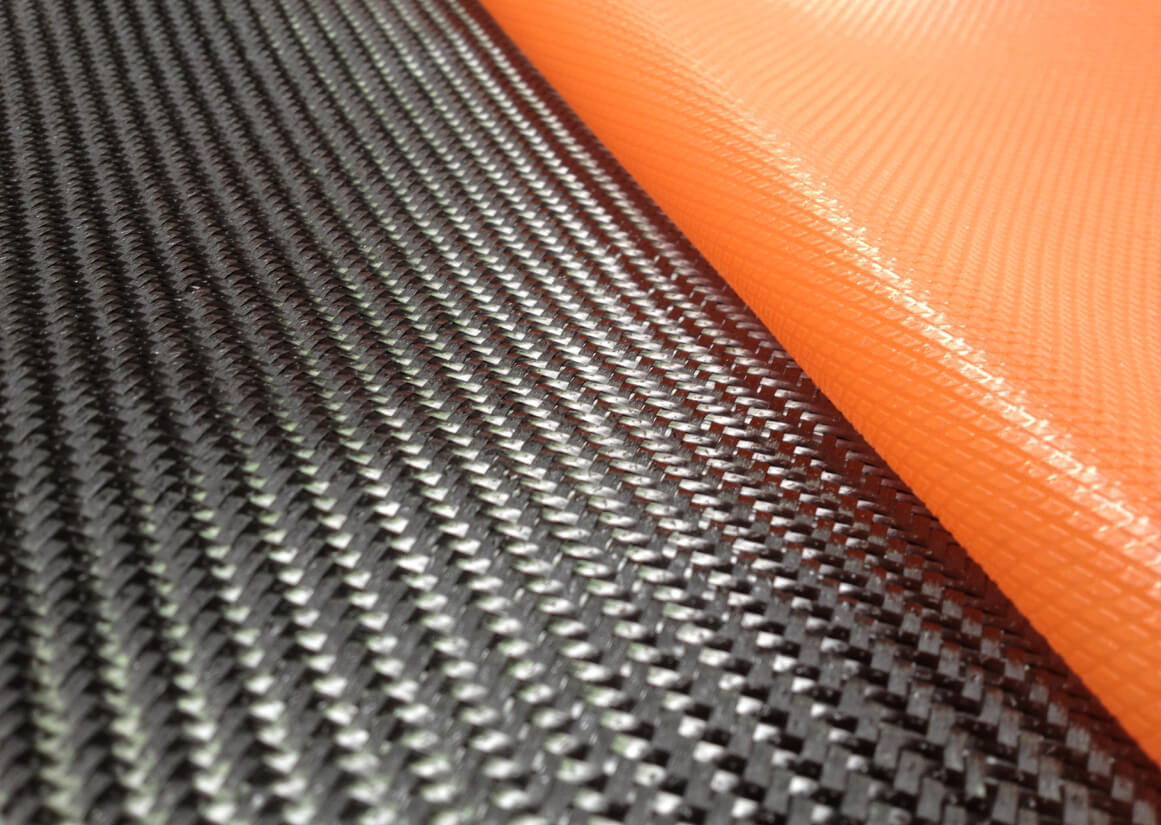

Their durability and strength relative to their light weight allow previously impossible projects to be realised and have resulted in innovations in the aerospace, automotive, and building industries, among others.

At GMS Composites, we take pride in being your single-source solution for a wide array of composite materials and technologies. Our expertise extends across a comprehensive range of prepregs, fabrics, resin systems, and advanced manufacturing processes. By consolidating your material needs with us, you benefit from efficient supply chain management. The advantages are clear: reduced complexity, simplified procurement, and enhanced operational efficiency. With a single supplier for multiple materials and technologies, you gain the convenience of consolidated invoicing, optimised logistics, and greater flexibility in managing your projects. Experience the ease of working with a partner dedicated to making your supply chain as efficient and cost-effective as possible.

GMS Composites’ in-house expertise and R&D partnerships with research institutes and universities allow them to formulate, test, and develop bespoke solutions for your project’s demands.

From initial prototypes to small batches for niche applications to high-volume orders, GMS Composites’ supply chain and warehouse infrastructure/expertise allow them to manufacture your product in the exact quantities required.

GMS Composites’ ability to rapidly develop and produce materials for your project allows you to accelerate your deadlines, enabling you to launch products faster and more cost-effectively.

Learn about solutions our team has provided for clients across multiple industries.

Our clients

© GMS COMPOSITES 2023