In the highly-competitive field of automotive design and manufacturing, the quest for innovation, efficiency, and sustainability is unending. As the industry accelerates towards a future dominated by lightweight, high-performance, and eco-friendly vehicles, the role of composite materials has never been more pivotal.

GMS Composites is a driving force in this revolution, bringing the future closer every day with our unparalleled expertise and experience.

The Rise of Composite Materials in Automotive Innovation

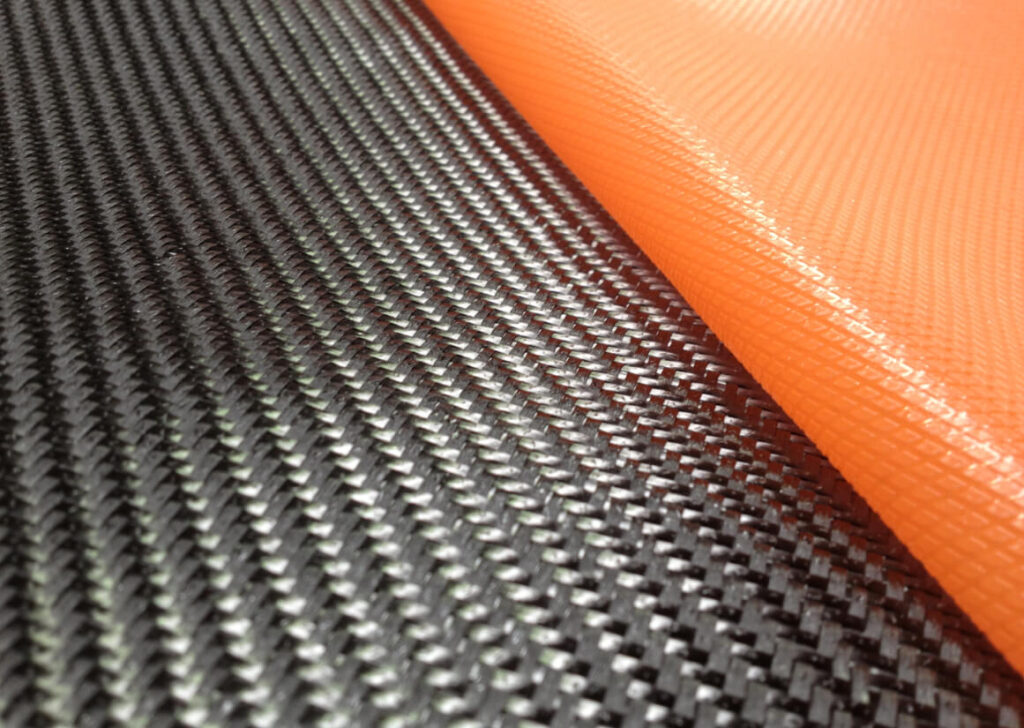

The automotive industry’s embrace of composite materials is a response to the constant need for vehicles that are both lighter and stronger, capable of delivering enhanced performance while reducing environmental impact and fuel consumption.

Composites, with their exceptional strength-to-weight ratios, offer a solution that traditional materials cannot match. Their versatility allows for the design and production of components that push the boundaries of innovation, setting new standards for speed, safety, and sustainability.

GMS Composites: Pioneering Automotive Solutions

With our partnerships with cutting-edge research facilities and universities around the world, GMS Composites is able to develop, test, and produce bespoke composite solutions for the automotive industry’s exacting and specific demands. Be it a door panel that shaves a fraction of a second off a lap time or a fluid tank with half the weight of the previous iteration, GMS Composites can produce the material to make the impossible possible.

Custom Solutions for Tomorrow’s Vehicles

Understanding that innovation in automotive design requires more than just advanced materials, GMS Composites offers tailored solutions that address the unique challenges of each project.

We take a hands-on approach to its partnerships, offering expert guidance, technical support, and end-to-end project management. This comprehensive service model ensures that clients not only receive the best materials but also benefit from the expertise and insight needed to succeed and dominate in a highly competitive market.

Charging into the Future

Composite materials are pivotal in advancing electric vehicle (EV) technology. Weight reduction is a crucial part of extending the range of EVs, and composite materials, which allow for comparable or even improved structural strength at a fraction of the weight of traditional materials, are ideal for the job. This is especially important for offsetting the heavy batteries that power EVs, allowing them to compete with internal combustion vehicles.

These innovative materials are employed in key components such as leaf springs and battery boxes, enhancing the vehicle’s performance, safety, and efficiency. By leveraging the capabilities of advanced composites, EV manufacturers are overcoming design challenges and pushing the boundaries of automotive technology.

Staying Ahead of the Pack

GMS Composites is not just a supplier of composite materials; we’re a pivotal player in the transformation of automotive design. With our comprehensive approach, commitment to innovation, and tailored solutions, GMS Composites is driving the future, making previously impossible projects possible for clients across the globe, in not just the automotive field but a range of industries.

To find out more about how composite solutions can give you the edge, contact us today.

FAQs

What makes composite materials transformative in automotive design?

Composite materials are transformative due to their exceptional strength-to-weight ratios, versatility, and resistance to environmental factors. These properties enable the design and production of vehicles that are lighter, stronger, and more efficient, paving the way for advancements in performance, safety, and sustainability.

How does GMS Composites contribute to automotive innovation?

GMS Composites contributes to automotive innovation by developing advanced composite materials tailored to the specific needs of the automotive industry. Through partnerships with research institutions, GMS Composites provides solutions that enable manufacturers to overcome design challenges and achieve groundbreaking results.

What are some examples of automotive parts manufactured using GMS Composites’ materials?

GMS Composites’ materials are used in a wide range of automotive parts, including lightweight body panels, durable engine components, aerodynamic spoilers, and advanced interior structures. These components contribute to improved vehicle performance, enhanced safety features, and greater fuel efficiency.

How does GMS Composites ensure the quality and performance of their composite materials?

GMS Composites ensures the quality and performance of its materials through rigorous testing, strict quality control processes, and continuous research and development. Our commitment to quality and partnerships with leading research facilities guarantee that all materials meet the highest standards of excellence.

Can GMS Composites provide solutions for electric and hybrid vehicles?

Yes, GMS Composites is well-equipped to provide solutions for electric and hybrid vehicles. Our expertise in lightweight and high-strength composite materials is particularly beneficial for these types of vehicles, where efficiency and battery range are paramount. By reducing the overall weight of the vehicle, composite materials help to extend battery life and improve performance, making them an ideal choice for the next generation of electric and hybrid vehicles.